50+ Years Experience

We have been providing non-destructive testing services since 1973

Certified in Canada & USA

We are certified by the Canadian Welding Bureau (C.W.B.) to C.S.A. Standard W178.1 and the American Welding Society (AWS) to AWS QC1. We provide service to procedures and codes, including C.S.A. W59 and ASME.

Service Area

Primarily serving Niagara and the surrounding region. We can accommodate out of area inspections as well.

Non-Destructive Testing Services

Radiography

Radiography produces a visual picture on radiography film. We use X-Ray and Iridium.

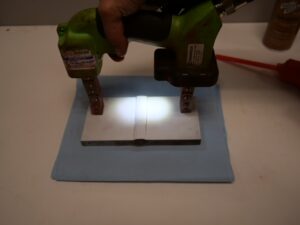

Magnetic particle

Detection of surface and near-to-surface discontinuities in things like welds, stress areas

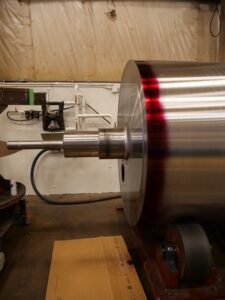

Ultrasonic Testing

High frequency sound can be used to detect internal

discontinuities in welds, plates

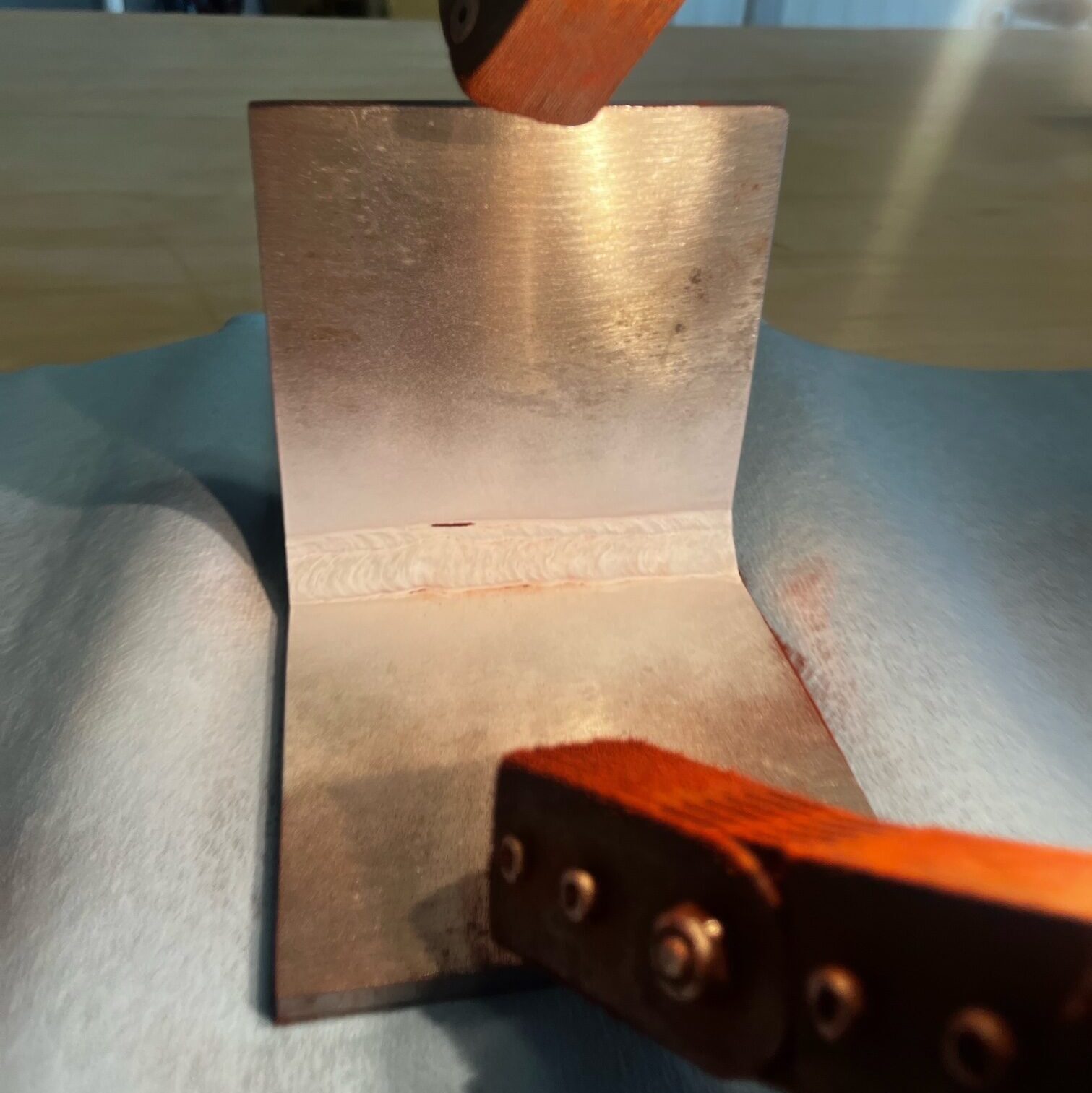

Liquid Penetration

Liquid Penetration is used to detect surface discontinuities in non-porous materials

Crane / Heavy Equip

We inspect cranes and heavy equipment

Hardness Testing

An impact test can be used to verify material hardness

Visual Inspection

We can inspect to ensure structures conform to builder’s intentions and code

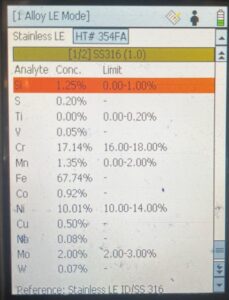

Positive Material Identification

Detect and measure the concentration of elements in substances such as alloys

More Information on Testing Services

X-ray testing of light allow materials or gamma inspection of welded structures can be performed. Radiography can determine the internal volumetric soundness of material varying from very thin to sections several inches thick. Our equipment is portable so that performance of the inspection and processing of the film can be done on site allowing for quick turnaround times and fast accurate results.

Our Technicians

We strive to employ experienced, highly trained, multi-disciplined technicians that are capable of providing you with the best non destructive testing (NDT) expertise possible.

We are certified to these standards: